Pars Atlas Turbine:

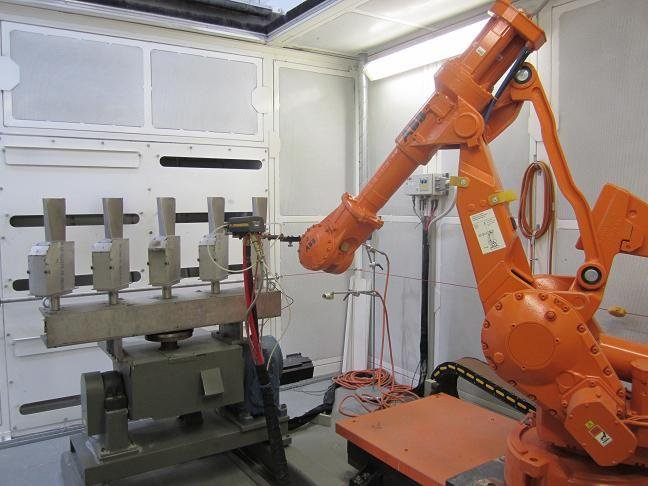

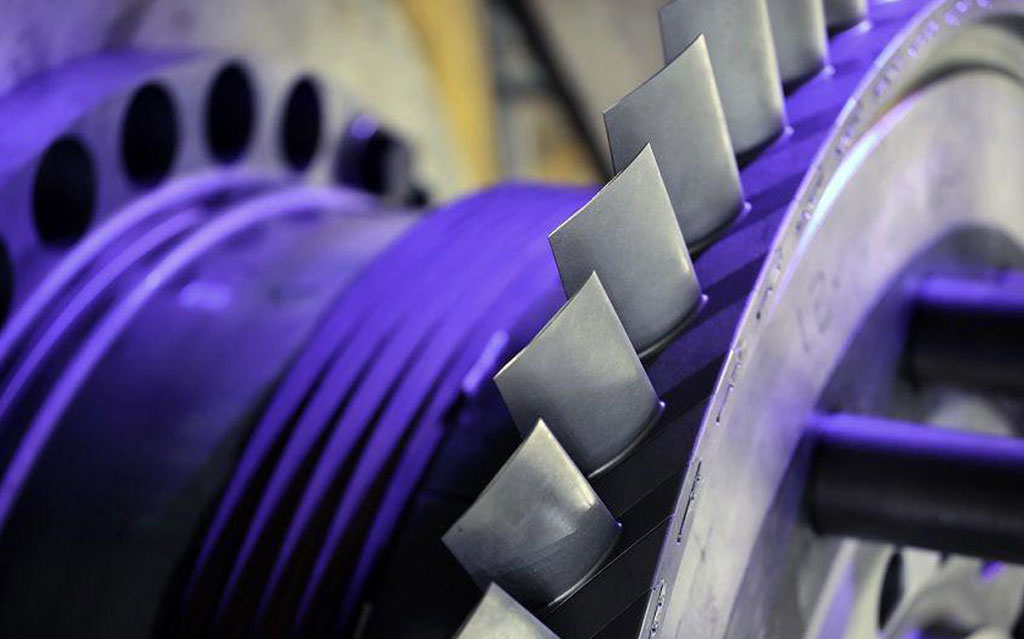

The compay is located in Malard city one hour drive far from Tehran , this 5000 sqm workshop is an independent specialized company with all facilities for repair of hot gas components. consisted of Welding , brazing , cleaning , heat treatment and coating departments.However the main field of PARS ATLAS TURBINE company which is established in 2002 is referbishment of Rotor and stationary of gas turbine but its experinced provide:

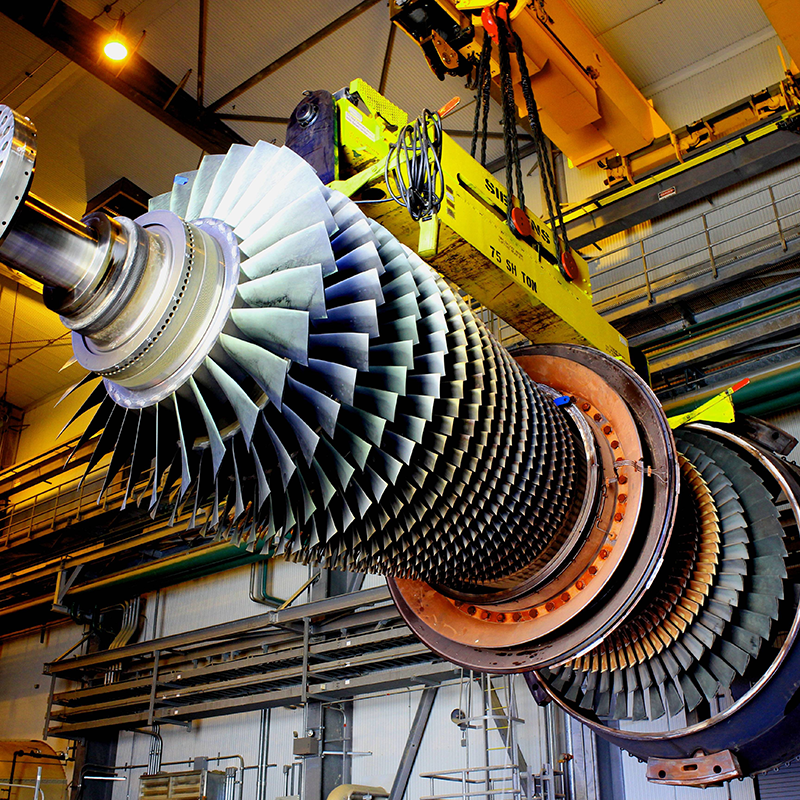

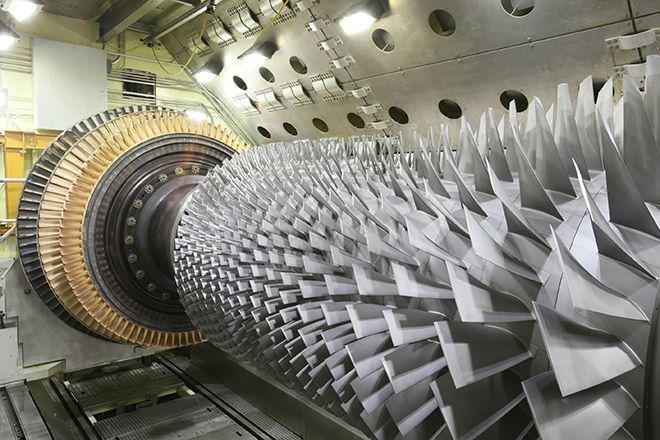

1.Overhaul of GEF5 and GEF6 Rotor

2.Full Overhaul of siemens gas turbine such as SGT100-400

3.Suppling components from best OEM or non OEM components